Aplication

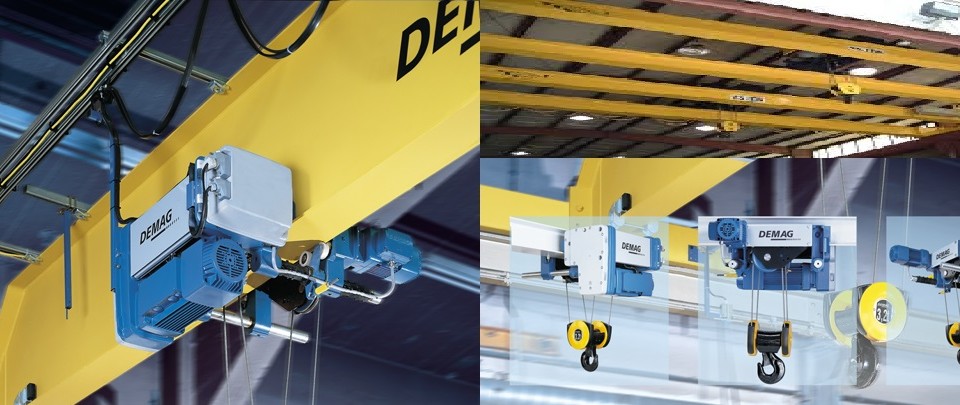

Crane bridge revamping in pool area

Industry

Nuclear Energy

Client

- Atucha I Power Plant

- Atucha II Power Plant

Area

Automation

Hardware

- Siemens S7-1200 CPU

Software

- Siemens TIA Portal V13

- Crane 3D Vision Lite

Request

In the pool area for hazardous materials, in Atucha I and Atucha II, the client needed to readapt the existing overhead crane.

One of his requests was to implement a system to slow down the crane speed in certain areas or stop it where necessary.

This is because in these areas cranes should not be handled in pools or they must do it at a lower speed, depending on the load to be transported.

One of his requests was to implement a system to slow down the crane speed in certain areas or stop it where necessary.

This is because in these areas cranes should not be handled in pools or they must do it at a lower speed, depending on the load to be transported.

Implemented Solution

To solve this problem, we offered our client a reduced version of Crane 3D Vision -Crane Vision 3D Lite-, since the event log was not required.

For the selection of the distance sensors responsible for determining the position of the bridge, a survey of the premises was made and we looked for the best sensors that would not be affected by the environmental conditions where they would be installed.

Based on this and on the crane model, a control board was constructed and mounted with Siemens PLC, S7-1214 CPU. In this PLC, the crane control, alarms and warnings were programmed, displayed through a light siren.

The communication between the control board and the Crane 3D Vision software is done by a wireless switch located on the overhead crane.

For more information on Crane 3D Vision visit

http://antaresautomation.com/usa/crane-3d-vision/

For the selection of the distance sensors responsible for determining the position of the bridge, a survey of the premises was made and we looked for the best sensors that would not be affected by the environmental conditions where they would be installed.

Based on this and on the crane model, a control board was constructed and mounted with Siemens PLC, S7-1214 CPU. In this PLC, the crane control, alarms and warnings were programmed, displayed through a light siren.

The communication between the control board and the Crane 3D Vision software is done by a wireless switch located on the overhead crane.

For more information on Crane 3D Vision visit

http://antaresautomation.com/usa/crane-3d-vision/