Aplication

Revamping PLC gasket welding machine

Industry

Manufacture - Plastic

Client

Rehau Plant- Rosario, Argentina

Area

Automation

Hardware

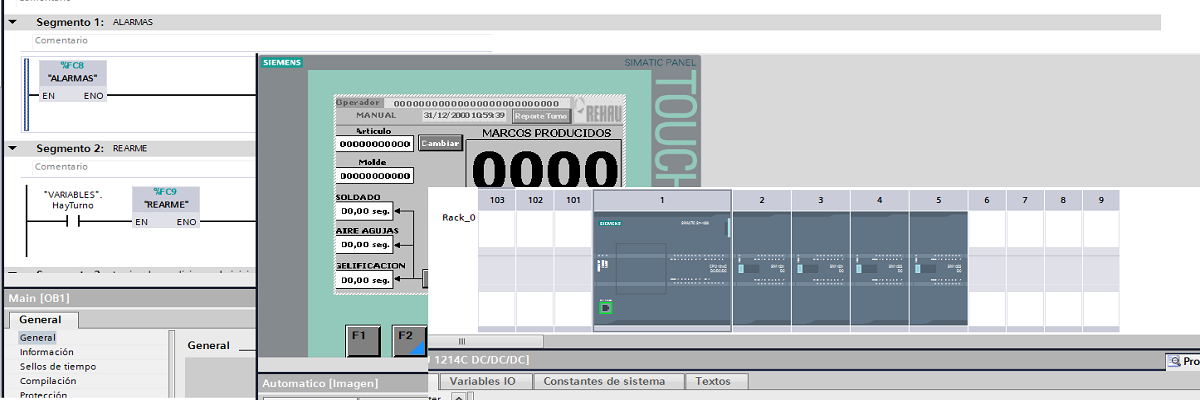

- Siemens S7-1214 PLC

- Siemens HMI KTP-600

Software

- TIA Portal V13

Requirements

The client wanted to upgrade his plant automation platform, which had an obsolete technology. This upgrade included the PLCs and HMIs in all of his gasket welding machines.

They had a Siemens S5 PLC and a basic OP screen, which are discontinued products and so no spare parts are available in the market.

They had a Siemens S5 PLC and a basic OP screen, which are discontinued products and so no spare parts are available in the market.

Implemented Solution

We offer our client to change the Siemens S5 PLC and OP screen for a Siemens S7-1200 PLC and HMI KTP600. One advantage of this new technology is the possibility of establishing an Industrial Ethernet network in the near future..

The upgrade was done in one of the machines taken as a reference, together with the client maintenance personnel. After the testings, debugging and commissioning had been performed, the source codes were provided to allow the client to repeat the work done by Antares in all of his gasket welding machines.

Tasks that were carried out:

The upgrade was done in one of the machines taken as a reference, together with the client maintenance personnel. After the testings, debugging and commissioning had been performed, the source codes were provided to allow the client to repeat the work done by Antares in all of his gasket welding machines.

Tasks that were carried out:

- Reengineering of the PLC logic and functionalities of the machine.

- Software programming of the machine in TIA Portal 13.

- HMI programming.

- Setting up the communication between the HMI and PLC.

- Programming the alarms requested by the client.

- Commissioning

- Project Documentation: User guide and Maintenance manual.