Aplication

Improvements in Extruder Pump

Industry

Manufacture - Plastic

Client

Rehau Plant in Rosario, Argentina

Area

Automation

Hardware

- Siemens S7-1214 PLC

- Siemens HMI KTP-600

Software

- TIA Portal V13

Requirements

The client needed to install a pressure pump, a gear-type pump, at the outlet of the extruder to work with greater percentage of recovered material without losing the quality in the final product.

He already had the pump, which was controlled by an old and obsolete logic.

He already had the pump, which was controlled by an old and obsolete logic.

Implemented Solution

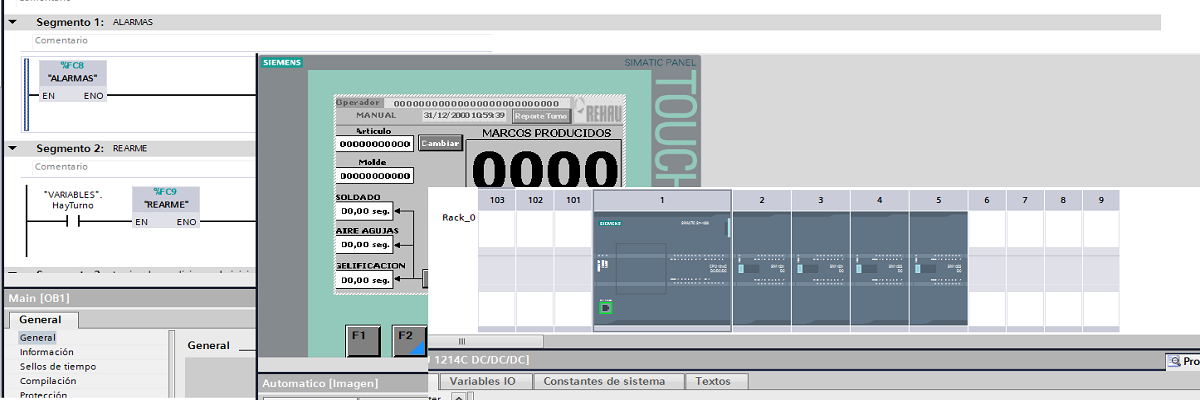

It was proposed to install a Siemens S7-1200 PLC and a Siemens KTP600 HMI screen to change the obsolete control logic for a modern digital one, which is also interchangeable with other sectors of the same line.

The control of the inlet pressure to the pump was achieved under the logic of a PID controller integrated in the PLC. Moreover, the temperature control of the different zones of the pump was also implemented under PID logic and PWM outputs from the PLC. Everything is monitored and configured from Siemens KTP600 HMI screen.

Tasks that were carried out:

The control of the inlet pressure to the pump was achieved under the logic of a PID controller integrated in the PLC. Moreover, the temperature control of the different zones of the pump was also implemented under PID logic and PWM outputs from the PLC. Everything is monitored and configured from Siemens KTP600 HMI screen.

Tasks that were carried out:

- Made and assembly of the new PLC board.

- Software programming of the machine in TIA Portal 13.

- HMI programming.

- Setting up the communication between the HMI and PLC.

- Implementation of alarm systems, which was previously non-existent.

- Commissioning.

- Project Documentation: User guide and Maintenance manual.

- Operator training.